ENGR2330 - Intro to Mechanical Prototyping

Short course projects for the semester are listed below in chronological order.

Some of the project results were also captured in informal videos shot by students in and outside of class.

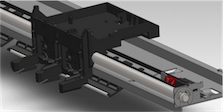

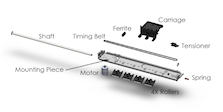

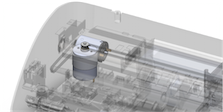

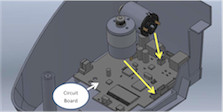

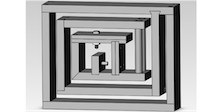

Printer "Mechtopsy"

A complex electromechanical system is disassembled (as a group) in the real world and modeled and reassembled (virtually) using computer aided design (CAD) tools.

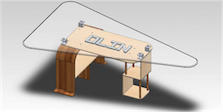

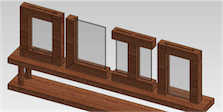

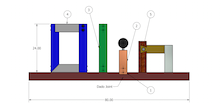

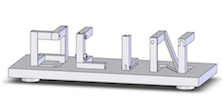

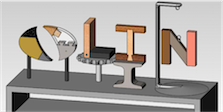

Inspired by Olin

Students design assemblies inspired by the word "Olin" using seven different types of structures, multiple joining techniques, and a host of mechanical fasteners.

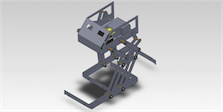

Sheet Metal

Beginning with prototypes in sheet metal, teams of 4-5 students design and construct legged walking machines that can be actuated with a maximum of two motors.

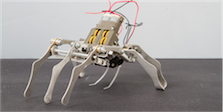

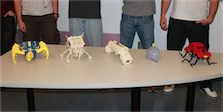

3D Printing

To explore the unique advantages afforded by the 3D printing process, students developed playful prototypes of legged crawlers. Again, the requirement was something legged that could be driven by a maximum of two motors. Projects included never before attempted features like spherical joints, printed spiral clock springs, and an entirely printed, functional, (Theo Jansen) linkage.

Final Projects

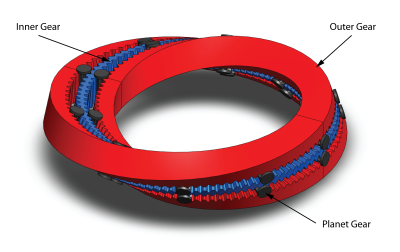

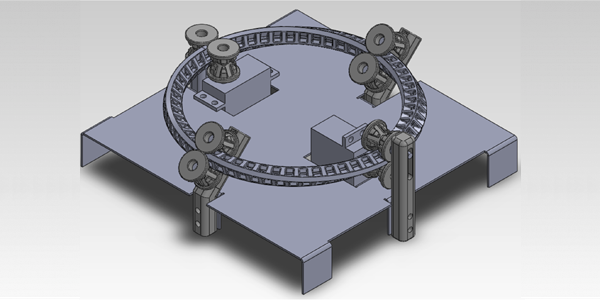

For their final projects teams could choose between prototyping a vehicle/crawler or working on the design challenge of building an actuated Möbius gear. Both projects were required to integrate all the prototyping techniques covered in the class - sheet metal, 3D printer, and molding with two-part elastomers. Three teams opted to work on the Möbius gear challenge, and two teams decided to build "vehicles."