ENGR2330 - Intro to Mechanical Prototyping

Short course projects for the semester are listed below in chronological order.

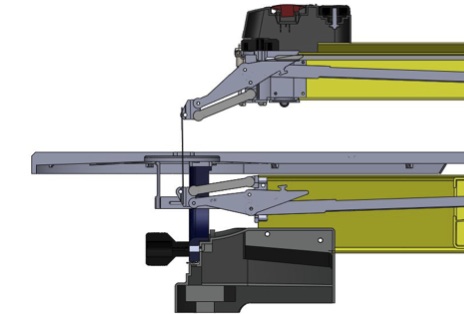

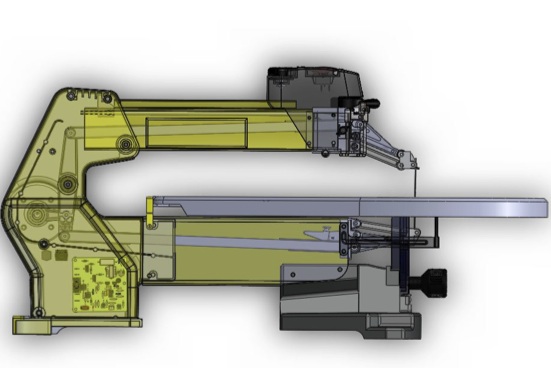

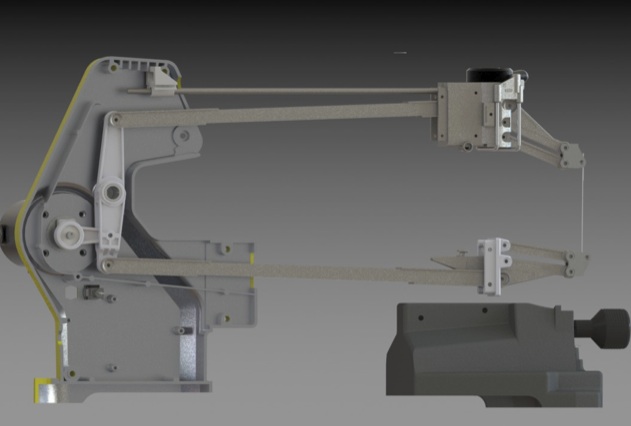

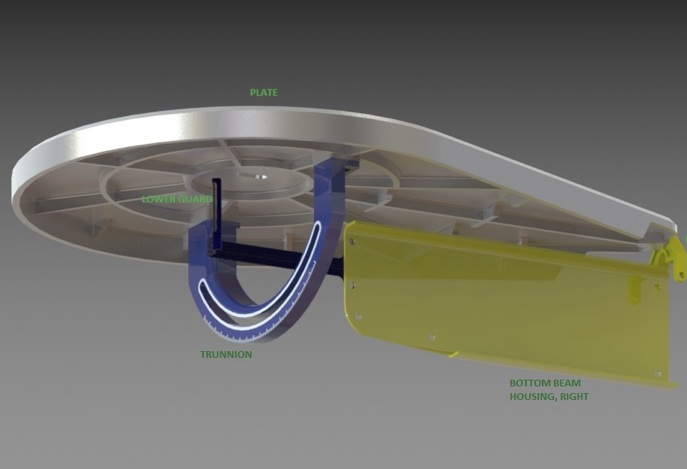

"The Mechtopsy"

A complex electromechanical system is disassembled (as a group) in the real world and modeled and reassembled (virtually) using computer aided design (CAD) tools.

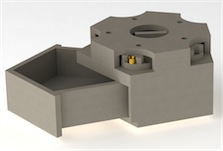

The Olin Box

Students design simple boxes inspired by "Olin" using different types of structures, multiple joining techniques, and a host of mechanical fasteners.

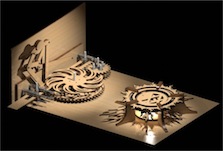

Planar Mechanisms

In this project, a team of four students designs and builds a board of planar mechanisms. The mechanisms may integrate or stand alone, but each team member is responsible for the design and analysis of one mechanism. Some popular choices are belt drives, gears, cams, Scotch yokes, and irises.

Final Projects

The final project was the design, fabrication, and testing of an underactuated hand. Underactuated systems have more degrees of freedom than actuators and typically rely on compliance in the system to determine the configuration. Student teams of three to four members generated three prototypes of their underactuated hands using laser-cut plywood, sheet metal, and 3D printing (fused deposition modeling or FDM).

Final prototypes were mounted to a robotic arm and competed in a grasping competition.